ENGINEERING, DESIGN,

AND CONSTRUCTION OF INDUSTRIAL EQUIPMENT

Our technical team, trained with transversal experience, is involved in the mechanisation and fine-tuning of each project, in order to optimise machining processes and manufacturing times, thanks also to the use of three-dimensional software such as CREO PARAMETRICS and AUTOCAD.

CAM solutions (SIGMANEST and ESPRIT), natively integrated with the management environment, allow our staff to operate efficiently and dynamically in prototyping processes, development, and optimisation of sheet-metal nesting and mechanical machining, ensuring greater competitiveness in the market.

The direct interconnection with the management system is able to monitor every aspect of production in real time, and on every machine. Productivity benefits enormously, making the process leaner and more manageable.

Palsider can handle the project in all its phases, from 3D design to the development and validation of dedicated, adjustable tools on all 3 axes, from prototyping to testing, through to industrial mass production.

Our technicians, whose training is constantly updated, support the customer from the initial stages of the project, suggesting best practices for each type of realisation, following the development of the work from the first stage to final project approval.

We use wear-resistant materials to make our products long-lasting, and work CNC frame works, turrets and binding frames.

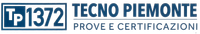

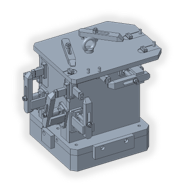

TACKING/WELDING TOOLS

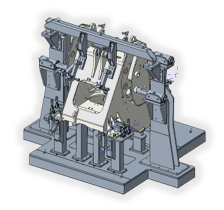

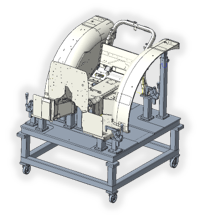

1-2 AXIS WORK POSITIONERS

MULTI-POSITION WELDING TOOLS

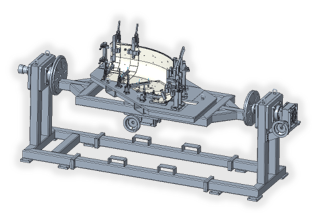

CNC MACHINING TOOLS

ASSEMBLY BENCHES

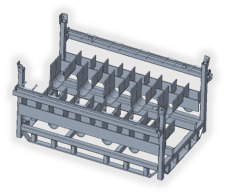

SPECIFIC AND RETOURNABLE CONTAINERS

Design and implementation of equipment

Palsider offers services for the design and manufacture of equipment (mechanical, pneumatic and hydraulic) of:

- Tacking and Welding

- Machining

- Assembly

- Operational testing

- Lifting accessories

- Internal and external handling

Our offer

In addition, to accommodate customer needs, we offer:

- Vectorialisation of freehand drawings

- Reverse engineering

- Production of user and maintenance manuals

- 3D simulation

- CE-marking

- Structural calculation and FEM analysis

- CAD-CAM integrated services